Choosing the Right Thermoforming Material for Your Packaging

Selecting the right material is one of the most critical decisions in thermoformed packaging. Each material offers distinct strengths, limitations, and applications that can affect product protection, production efficiency, sustainability, and shelf appeal. A misunderstanding at this stage can lead to wasted material, production delays, or packaging that fails to perform in real-world conditions.

Understanding the properties and ideal uses of common thermoforming plastics — PET, RPET, PP, PVC, HIPS, and ESD — equips packaging professionals to make informed choices. With this knowledge, it becomes easier to match products with the material that delivers the right combination of clarity, strength, barrier performance, and functional compatibility.

While technical expertise is important, the complexity of materials and applications means that partnering with an experienced packaging supplier can ensure that material selection aligns with product requirements, production capabilities, and long-term goals.

Polyethylene Terephthalate (PET)

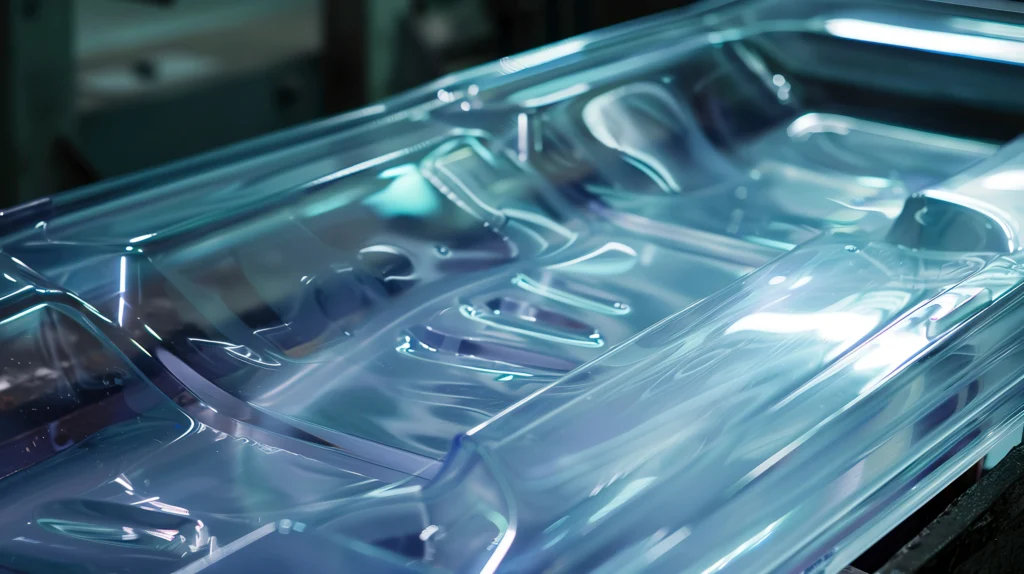

Polyethylene Terephthalate, commonly known as PET, is a clear, strong thermoplastic widely used in retail and food packaging. Its combination of optical clarity, mechanical strength, and barrier performance makes it a go-to choice for products that require both visual appeal and protection.

Key Properties and Strengths

Clarity and shelf impact: PET provides high optical transparency, allowing products to be visible while conveying a premium appearance.

Mechanical strength: PET maintains rigidity and structural integrity across a wide range of wall thicknesses, supporting stacking and transport.

Barrier performance: PET offers moderate resistance to moisture and oxygen, protecting products from environmental exposure over typical shelf life durations.

Process compatibility: It is highly thermoformable, allowing for detailed cavity shapes and consistent wall thicknesses.

Applications

- Blister packs for electronics or consumer goods

- Clamshell packaging for food items

- Retail trays requiring product visibility and structural durability

Recycled PET (RPET)

Recycled PET is derived from post-consumer PET, typically incorporating 50% or more recycled content. It offers many of the same properties as virgin PET while supporting sustainability initiatives and circular packaging goals, which are increasingly important in the food, beverage, and consumer goods industries

Key Properties and Strengths

Sustainability: RPET reduces environmental impact by reusing post-consumer plastics, helping brands meet ESG and regulatory goals.

Clarity and strength: Maintains comparable optical transparency and rigidity to PET, suitable for premium packaging applications.

Barrier performance: Provides moderate protection against moisture and oxygen, similar to PET.

Recyclability: RPET can often be recycled again, supporting circular material strategies.

Applications

- Food trays for fresh produce, baked goods, and ready-to-eat meals

- Clamshell and blister packaging for consumer products

- Retail trays where visibility and sustainability are both priorities

Polypropylene (PP)

Polypropylene (PP) is a versatile thermoplastic known for its heat resistance, chemical stability, and toughness, making it a common choice for food packaging and other applications requiring durability under temperature extremes.

Key Properties and Strengths

Heat tolerance: PP can withstand high temperatures, making it suitable for hot-fill, microwavable, or frozen food packaging.

Moisture resistance: Provides a strong barrier against moisture, helping maintain product quality.

Lightweight and durable: Offers structural integrity while minimizing material use and shipping weight.

Thermoformable: Supports complex shapes and consistent wall thickness for functional and protective packaging.

Applications

- Frozen or microwavable food containers

- Portion trays for ready-to-eat meals

- Packaging for products requiring moderate barrier protection combined with heat or chemical resistance

Polyvinyl Chloride (PVC)

Polyvinyl Chloride (PVC) is a rigid thermoplastic particularly well-suited for thermoformed packaging that requires defined shapes. Unlike PET or RPET, which prioritize clarity and premium shelf presentation, PVC excels at forming intricate cavities and detailed features with consistent wall thickness, making it ideal for small consumer goods and food trays where form and durability are key.

Key Properties and Strengths

High-detail thermoforming: Produces complex cavity shapes and crisp features consistently.

Structural rigidity: Maintains shape under handling, stacking, and transport.

Moderate clarity: Ensures product visibility while emphasizing form and precision over optical perfection.

Cost-effective: Offers a balance of performance and economics for medium-volume runs.

Applications

- Clamshell packaging for food items like bakery products and produce portioning

- Retail trays where defined shapes and protection are required

- Small consumer goods that need structured, precise packaging

High Impact Polystyrene (HIPS)

High Impact Polystyrene (HIPS) is a lightweight, durable thermoplastic valued for its toughness, printability, and structural stability. Unlike PET or RPET, which prioritize clarity, or PP, which excels under heat, HIPS is ideal for protective trays, display packaging, and applications that benefit from custom finishing or branding.

Key Properties and Strengths

Cost-effective: Offers an affordable solution without compromising quality, ideal for medium- to high-volume production.

Molding versatility: Thermoforms easily into complex shapes, supporting custom trays, cups, clamshells, and display packaging.

Printability: Smooth surface allows high-quality printing with screen or offset lithography for branding, product information, or decorative finishes.

Food safety: FDA-approved grades are suitable for direct food contact, supporting bakery, deli, and ready-to-eat applications.

Moisture resistance: Provides adequate barrier properties for short-shelf-life products, with certain grades offering improved resistance to cracking when in contact with fatty foods.

Applications

- Food trays and containers (e.g., bakery goods, cookies, deli items)

- Clamshell packaging and blister packs

- Point-of-purchase and retail display trays

ESD (Electrostatic Discharge) Materials

ESD-safe plastics are engineered to protect sensitive electronic components from damage caused by static electricity during handling, transport, and assembly. Even small electrostatic discharges — invisible to the human eye — can destroy microchips, sensors, and circuit boards. To prevent this, ESD materials incorporate conductive or dissipative additives that control surface resistivity, safely channeling electrical charges away from sensitive products.

While ESD packaging can be made from various base materials such as PET, PVC, or HIPS, the defining characteristic is its ability to manage electrical charge. This makes it essential for packaging in electronics manufacturing, assembly, and logistics environments where static control is a critical quality requirement

Key Properties and Strengths

Static protection: Designed to dissipate or shield against static charges, preventing electrostatic damage to components.

Material flexibility: Can be formulated as conductive, static-dissipative, or anti-static to meet different resistance specifications.

Durability: Offers the same mechanical strength and formability as the base resin (e.g., PET or HIPS), maintaining structural integrity in thermoformed packaging.

Cleanliness: Often produced in controlled environments to prevent particle contamination in high-precision electronics.

Visual clarity options: Depending on formulation, can be made transparent, translucent, or opaque to balance visibility and protection.

Applications

- Trays and clamshells for circuit boards, sensors, and small assemblies

- Component shipping trays used in automated pick-and-place systems

- Divider systems and in-process handling trays

- Protective enclosures for static-sensitive devices during manufacturing and transport

Working with the Right Packaging Partner

Every material has its strengths and its limits. Knowing how to align those characteristics with the demands of a specific product or production environment takes experience and technical understanding.

The right packaging partner brings practical insight into how each material performs in real-world conditions. They help ensure that tray geometry, flange design, and barrier needs are matched to the right material from the start.

Ready to explore which material is the best fit for your next thermoformed packaging project?