Exploring Polypropylene (PP) in Thermoformed Packaging

Packaging can be a make-or-break factor for products. Choosing the right material influences durability, performance, and how well a product connects with its customers when spotted on store shelves. For manufacturers and designers, every packaging decision carries real stakes, from protecting fragile items during shipping to meeting sustainability goals.

Polypropylene packaging offers a versatile solution for these considerations. Its strength, heat resistance, and recyclability give businesses the confidence to create reliable, high-quality packaging that performs under pressure. Understanding what polypropylene brings to the table allows teams to make smarter, more strategic choices that protect products and elevate the customer experience.

With the right material in place, companies can tackle their toughest packaging challenges and ensure their products reach the market safely. This post delves into polypropylene in depth, highlighting why it has become a trusted material for packaging used across various industries and applications.

What is Polypropylene Plastic?

Polypropylene (PP) is a durable, lightweight, and versatile thermoplastic polymer made from polymerized propylene monomers. Its balance of strength, flexibility, and resistance to heat and chemicals has made it a trusted material in modern packaging.

Compared to other common plastics such as PET or PVC, polypropylene excels at resisting cracking, warping, and chemical exposure. Its ability to withstand higher temperatures and retain structural integrity during shipping or storage makes it a dependable choice for products that face real-world challenges.

Beyond performance, polypropylene packaging also advances sustainability goals. Its low weight reduces shipping costs and material use, while its recyclability helps companies move toward greener operations.

For manufacturers and designers with complex packaging requirements, polypropylene provides a strong and versatile foundation. Its proven performance gives teams the confidence to solve difficult design challenges, protect products through demanding supply chains, and deliver a consistent, high-quality experience to customers.

Key Advantages of Polypropylene Packaging

Choosing the right packaging material can significantly impact a product’s success, from the warehouse to the consumer’s hands. Polypropylene gives businesses a powerful combination of strength, flexibility, and reliability, turning a common challenge—protecting and presenting products—into an opportunity to stand out in the market. With polypropylene, companies can address practical concerns, support sustainability goals, and create packaging that delivers both protection and impact.

Here are the key advantages that make polypropylene a material manufacturers and designers rely on:

Durability: Polypropylene resists cracking, warping, and impact damage, making it ideal for fragile or high-value products. The material ensures products arrive in perfect condition, even through complex shipping networks.

Heat Resistance: Polypropylene maintains its structure under elevated temperatures, which is essential for products that may be exposed to heat during transport, storage, or consumer use. For example, microwavable food containers benefit from the material’s ability to retain shape and performance.

Chemical Resistance: Many products in the pharmaceuticals, personal care, and industrial sectors come into contact with chemicals that can compromise packaging. Polypropylene withstands exposure to acids, bases, and solvents without degradation, protecting both the product and the consumer.

Lightweight and Cost-Efficient: Polypropylene is significantly lighter than many alternatives, reducing material usage and shipping costs. This makes it an efficient solution for large-volume production runs while maintaining the structural integrity needed to protect the product.

Recyclability and Sustainability: Many polypropylene solutions are recyclable, helping businesses reduce environmental impact and meet corporate sustainability goals. By selecting polypropylene packaging, companies can balance both performance and corporate social responsibility, delivering packaging solutions that align with both operational and environmental priorities.

Versatility in Design: Polypropylene can be formed into rigid sheets, films, or custom shapes, allowing for creative packaging designs that enhance branding, improve user experience, and fit unique product specifications. Its adaptability ensures that packaging meets both functional and aesthetic needs.

Together, these qualities make polypropylene a dependable choice for a wide range of packaging challenges. Its strength, resilience, and adaptability provide a solid foundation that supports diverse products and applications, making it easier for businesses to meet their customers’ needs and move confidently from design to delivery.

Industries and Applications of Polypropylene Packaging

Different industries face unique packaging challenges, from protecting fragile products to meeting strict regulatory requirements or creating designs that appeal to consumers.

Polypropylene has become a trusted material in packaging because it can be thermoformed to meet these specific needs. Its physical properties allow manufacturers to design packaging that supports operational efficiency and delivers a consistent experience for end users.

By understanding how polypropylene can be applied in each industry, businesses can make smarter decisions and gain a competitive edge.

Food & Beverage

In the food industry, packaging must protect products through every stage of production, shipping, and display while maintaining freshness and visual appeal. Polypropylene’s heat resistance and durability make it ideal for items exposed to temperature fluctuations, from frozen meals to ready-to-eat snacks. Its lightweight nature reduces material use and shipping costs, helping companies streamline operations.

Polypropylene is a great choice for produce or meat trays and clamshell containers for prepared meals. These formats keep food secure, easy to handle, and visually appealing on store shelves.

Pharmaceuticals & Healthcare

Secondary packaging in pharmaceuticals must protect products during transport and storage while meeting strict regulatory standards. Polypropylene offers chemical resistance, durability, and structural strength, ensuring blister packs, cartons, and other protective enclosures remain intact and secure.

It is commonly used for multi-unit cartons, blister cards, and molded trays that hold individual units together safely. These solutions keep products organized, reduce the risk of damage during handling, and help pharmaceutical companies maintain compliance and operational efficiency.

Consumer Goods & Retail

For consumer goods such as personal care items, toys, and other retail products, packaging must combine protection with presentation. Polypropylene’s thermoforming flexibility allows designers to create custom-fit solutions that hold products securely while showcasing them clearly.

Brands often rely on molded trays, clamshells, and display-ready packaging that protect delicate items, reinforce brand value, and create a strong shelf presence. These solutions help companies deliver packaging that is durable and visually compelling, giving customers a positive first impression on store shelves.

Industrial & Manufacturing

Industrial and manufacturing components require packaging that can withstand rough handling, chemical exposure, and the demands of complex production environments. Polypropylene provides a lightweight, durable solution that protects parts without adding unnecessary bulk.

It is ideal for thermoformed trays, custom inserts, and component carriers that fit precisely, minimizing damage during transport, improving workflow efficiency, and ensuring components arrive ready for use.

Across these industries, polypropylene packaging transforms material choice from a challenge into a strategic advantage. Its strength, versatility, and reliability allow companies to deliver products safely, optimize operations, and meet customer expectations with confidence.

Solving Packaging Challenges with Polypropylene

Polypropylene packaging gives businesses the strength and versatility they need to meet demanding requirements across industries. Its durability, chemical and heat resistance, and design flexibility allow teams to create packaging that performs under pressure and protects products at every stage.

By tailoring polypropylene to specific applications, manufacturers and designers can optimize operations, reduce waste, and support sustainability initiatives, turning packaging from a constraint into a strategic advantage.

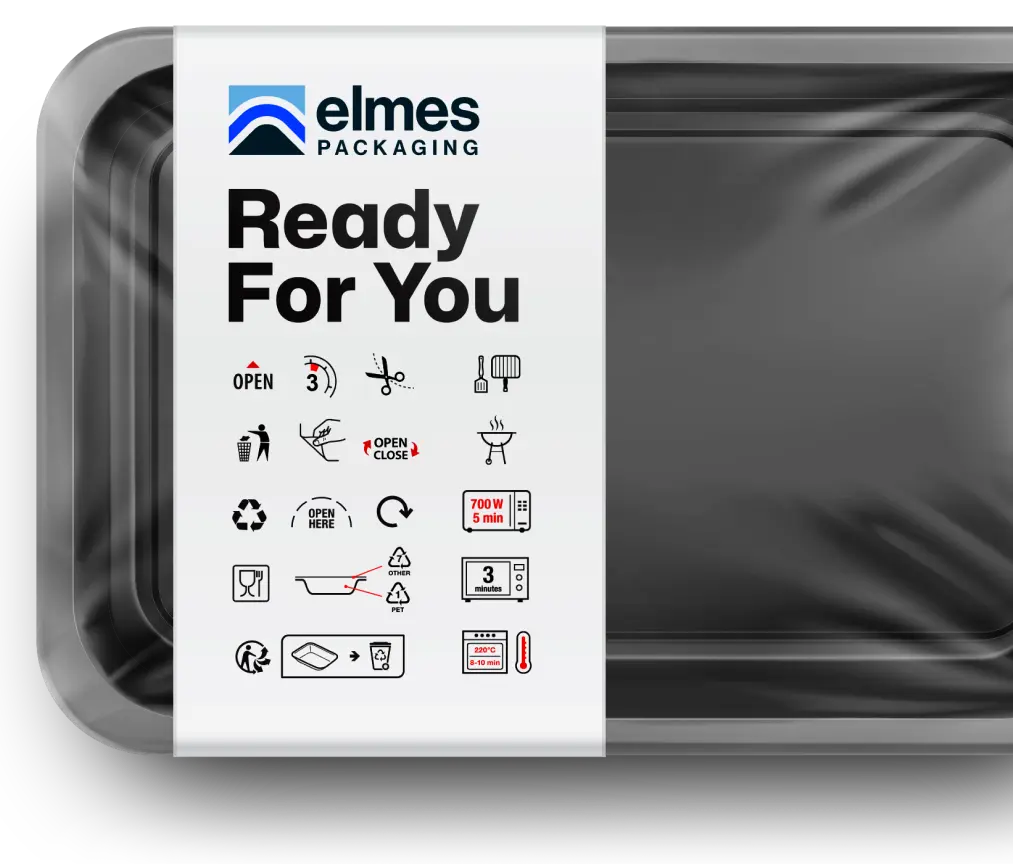

At Elmes Packaging, we take a hands-on approach, partnering with you to develop thermoformed solutions that protect products and enhance the customer experience. Whether it’s high-volume production or specialized secondary packaging, our expertise ensures your packaging is reliable, efficient, and engineered to deliver results.